What is Material Allocation Optimizer?

For deposits like limestone, clays, and iron ore, multiple products are often required, each made by blending various rock types to meet specific quality targets. Additionally, several processing methods are typically available to achieve the desired product specifications.

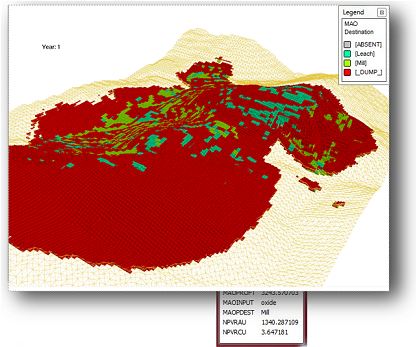

An example of MAO output

Studio NPVS’s Material Allocation Optimizer (MAO) uses a linear programming implementation to offer a complete solution for this type of optimal allocation problem, allowing the engineer to determine how to best transport, stockpile and treat material to generate all required products.

Note: Material Allocation Optimizer is fully integrated in Studio NPVS+ meaning a separate MAO optimization isn't required. As such, this module does not appear in Studio NPVS+.

Key points about MAO:

-

MAO inputs can include mine production, stockpiles, or externally sourced materials for blending.

-

MAO destinations may be processing methods or stockpiles, which can also serve as future inputs.

-

Destinations can have multiple quality targets, defined as element rates or ratios.

-

Destination capacities vary: unlimited (e.g., leach pads), limited (e.g., stockpiles), or targeted (e.g., processing plants).

-

Global constraints can enforce fixed rock type ratios for processing plant inputs.

-

Destinations may have positive or negative costs; negative costs represent selling prices, enabling complex, time-varying product definitions.

MAO doesn’t alter the mining sequence

MAO optimizes material destinations and stockpiling to meet product delivery goals. For each block, it outputs the optimal destination and inherits data from the Scheduler’s OES. MAO is a powerful tool for assessing whether the mine plan can meet variable product demands and adapt to changing sales contracts over the mine’s life.